Storage:

Safe & Efficient

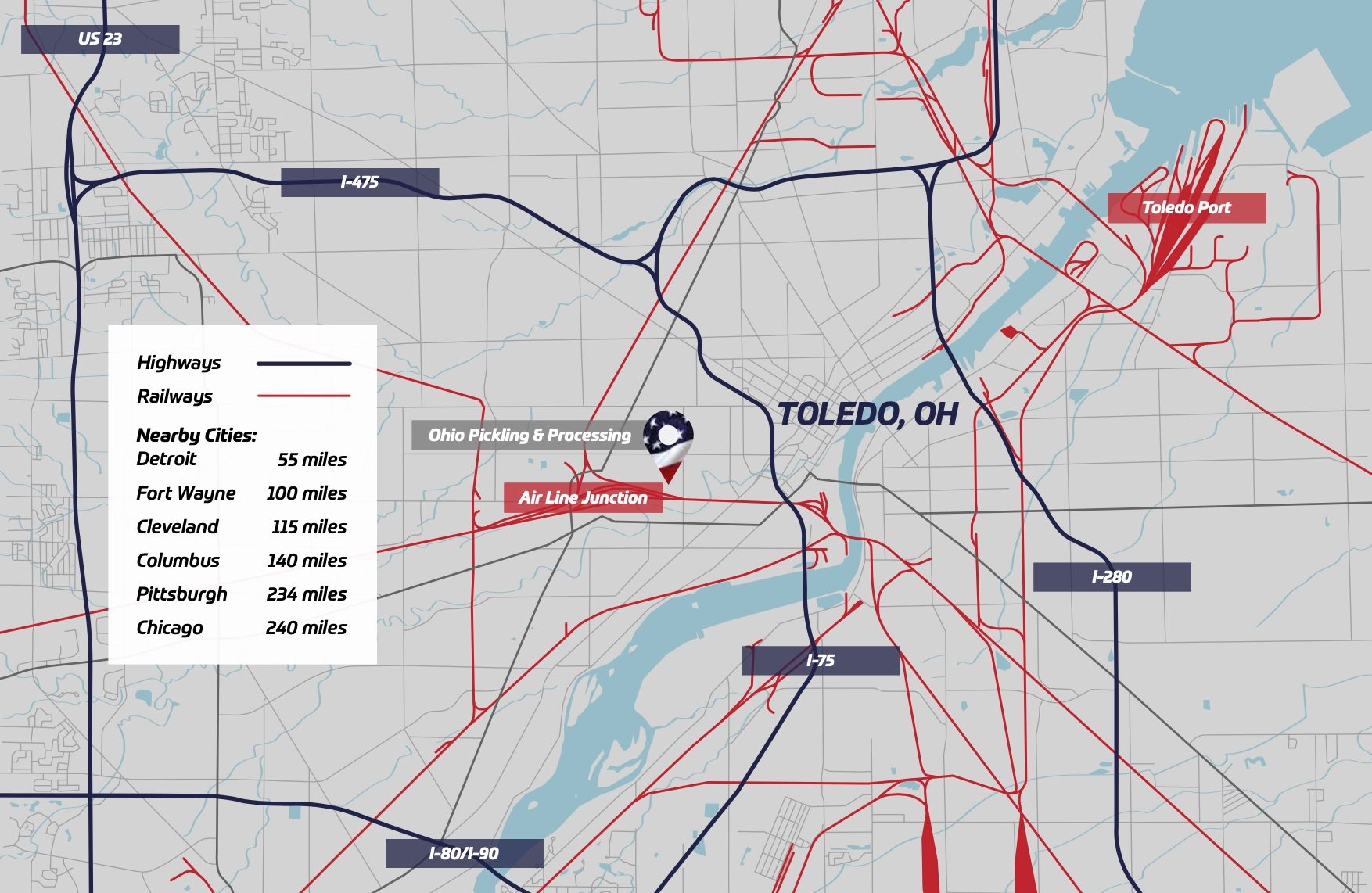

Ohio Pickling & Processing has a large 200,000 square foot climate-controlled warehousing facility for safe storage of customers' inventory. An additional 15 acres of outdoor storage is used for pre-process material that does not require indoor storage. With four overhead cranes (up to 35 ton capacity) and an expansive receiving area with direct rail service, delivery and shipping of customers' product is efficient and secure.